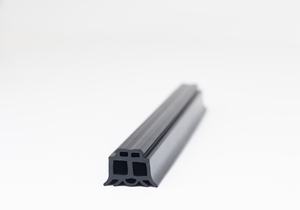

Aluminium rubber, also known as aluminum elastomer, is a composite material consisting of aluminum particles or flakes dispersed within a rubber matrix. This unique combination harnesses the properties of both aluminum and rubber, resulting in a material with diverse applications and advantageous characteristics.

The rubber matrix provides flexibility, resilience, and elasticity to the material, making it suitable for various dynamic applications where traditional rigid materials would fail. It enables the aluminium rubber composite to withstand deformations, vibrations, and impacts, making it ideal for applications requiring damping and shock absorption.

The presence of aluminum particles within the rubber matrix enhances several key properties of the material:

- Thermal Conductivity: Aluminum is an excellent conductor of heat. When dispersed within the rubber matrix, it improves the thermal conductivity of the composite material. This property is beneficial in applications where heat dissipation is crucial, such as in electronic devices or automotive components.

- Electrical Conductivity: Similarly, aluminum’s intrinsic electrical conductivity is preserved in the composite. This makes aluminium rubber suitable for applications requiring electrical grounding or shielding, such as in electromagnetic interference (EMI) shielding applications in electronics.

- Lightweight: Despite the presence of aluminum, the overall density of the composite remains relatively low due to the lightweight nature of rubber. This makes aluminium rubber an attractive option in applications where weight reduction is essential, such as aerospace or automotive industries.

- Corrosion Resistance: Aluminum possesses inherent corrosion resistance due to the formation of a protective oxide layer on its surface. When incorporated into a rubber matrix, the aluminum particles are shielded from direct contact with corrosive environments, further enhancing the material’s resistance to corrosion.

- Mechanical Strength: While rubber provides flexibility, the inclusion of aluminum particles can enhance the mechanical strength of the composite. This results in a material that can withstand mechanical stresses and strains more effectively than conventional rubber materials.

Applications of aluminium rubber are diverse and span various industries:

- Automotive: Aluminium rubber is used in automotive suspension systems, engine mounts, and vibration isolation components to dampen vibrations and reduce noise.

- Electronics: It finds applications in electronic enclosures, gaskets, and seals for EMI shielding and thermal management.

- Aerospace: Aluminium rubber is employed in aircraft structures, where its lightweight, damping, and thermal properties are advantageous.

- Construction: It can be used in building materials for vibration damping, seismic isolation, and thermal insulation.

- Marine: Aluminium rubber is utilized in marine applications for corrosion-resistant seals, gaskets, and vibration isolation mounts.

Overall, aluminium gaskets represents a versatile composite material with a wide range of applications, offering a balance of mechanical, thermal, electrical, and corrosion-resistant properties derived from its unique combination of aluminum and rubber constituents. Its continued development and utilization contribute to advancements in various industries requiring materials with exceptional performance characteristics.