EPDM rubber gaskets are versatile sealing solutions renowned for their exceptional durability, resilience, and resistance to various environmental factors. These gaskets are widely used across industries for sealing applications where reliable performance under demanding conditions is paramount.

One of the key attributes of EPDM rubber is its excellent weathering resistance, making it suitable for outdoor applications where exposure to sunlight, ozone, and harsh weather conditions is common. This weather resistance ensures that EPDM gaskets maintain their integrity and sealing properties over extended periods, even when subjected to UV radiation and temperature variations.

Furthermore, EPDM rubber exhibits impressive chemical resistance, standing up well against a wide range of chemicals, acids, alkalis, and polar substances. This chemical inertness makes EPDM gaskets suitable for use in industries such as chemical processing, pharmaceuticals, and food and beverage, where exposure to diverse chemical environments is prevalent.

EPDM rubber gaskets also possess outstanding thermal stability, retaining their flexibility and sealing effectiveness across a broad temperature range, from sub-zero temperatures to elevated heat levels. This characteristic makes them suitable for applications in both cold and hot climates, as well as in systems where temperature fluctuations occur regularly.

Moreover, EPDM gaskets offer excellent electrical insulation properties, making them ideal for sealing electrical enclosures, junction boxes, and other electronic applications. Their insulating capabilities help prevent electrical leakage and ensure the safety and reliability of electrical systems.

In addition to their resilience and chemical resistance, EPDM rubber gaskets are known for their compression set resistance, meaning they can maintain their original shape and sealing performance even after prolonged compression. This feature is crucial for ensuring leak-free seals in applications where gaskets are subjected to continuous compression or cyclic loading.

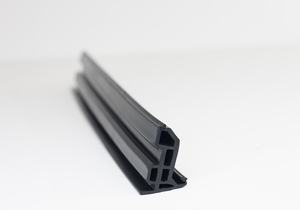

EPDM gaskets are available in various shapes, sizes, and thicknesses to suit diverse sealing requirements, including O-rings, flat gaskets, flange gaskets, and custom-molded profiles. They can be fabricated using different manufacturing processes such as compression molding, injection molding, or extrusion, allowing for customization to meet specific application needs.

In summary, EPDM rubber seals offer a combination of weather resistance, chemical compatibility, thermal stability, electrical insulation, and compression set resistance, making them an indispensable sealing solution across a wide range of industries and applications. Their reliability, longevity, and versatility make them a preferred choice for sealing critical systems and equipment in challenging environments.