Seals concrete pipes is essential to prevent leaks and maintain the integrity of the piping system, especially in wastewater, stormwater, and drainage applications. Here are some common types of seals used for concrete pipes:

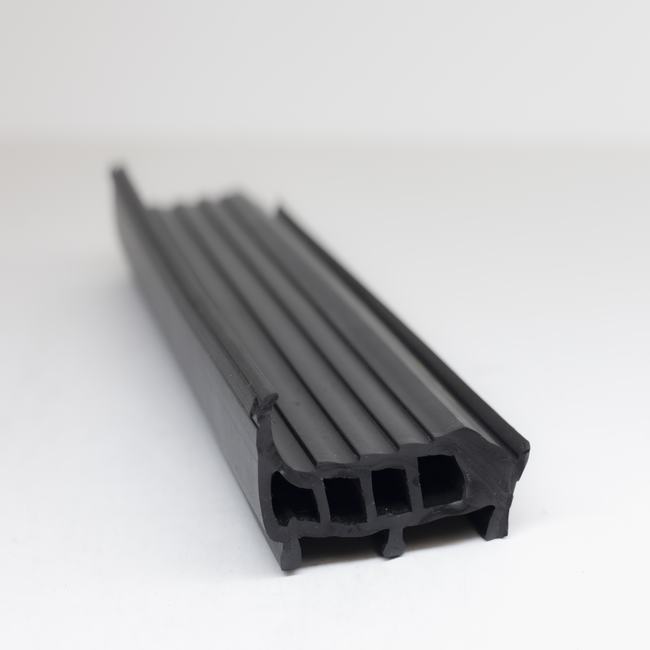

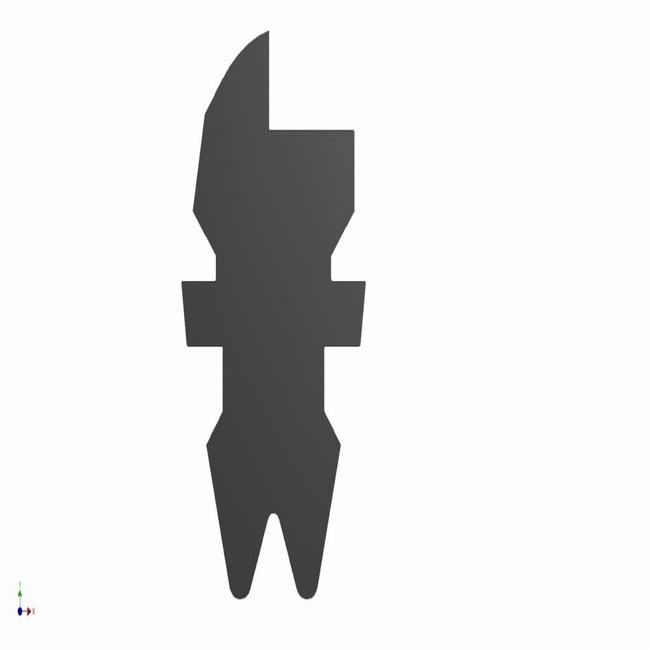

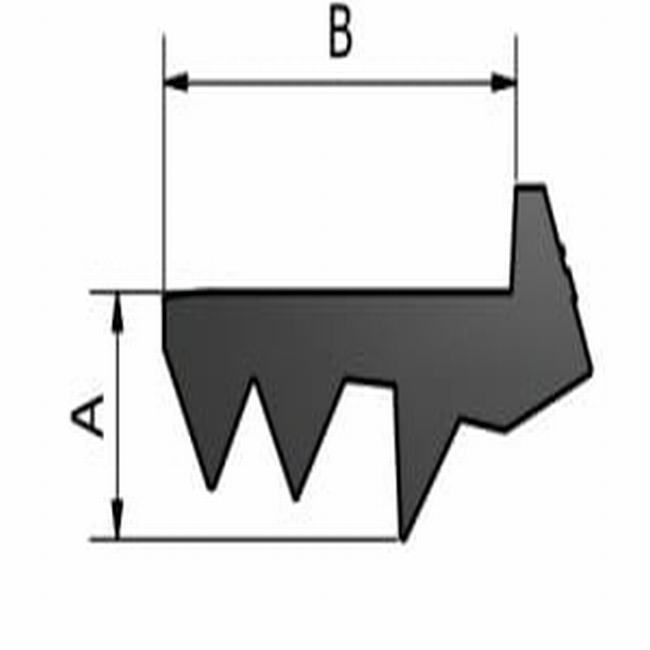

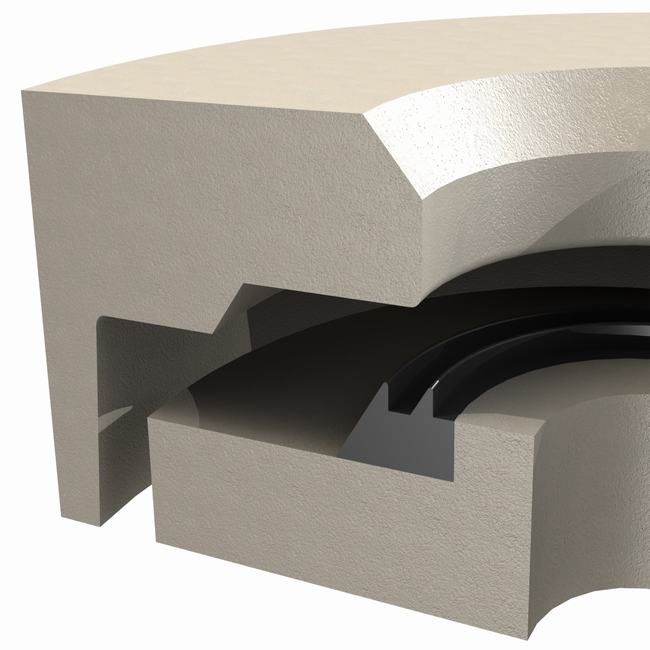

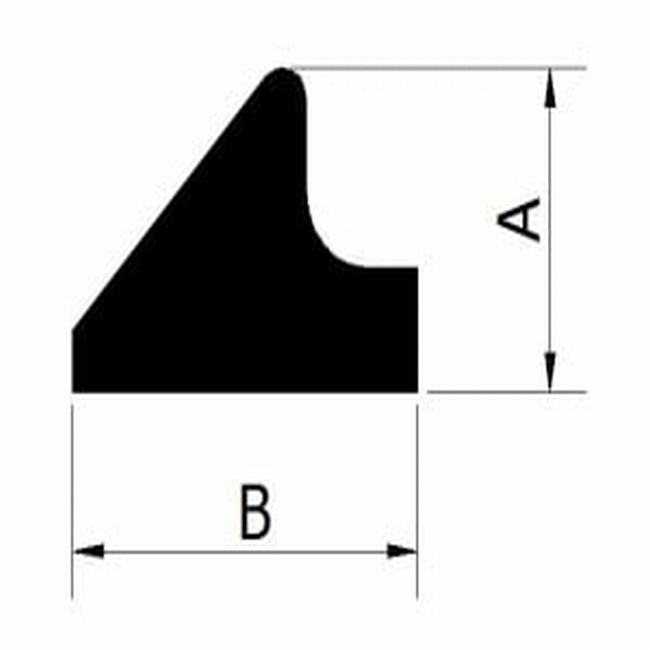

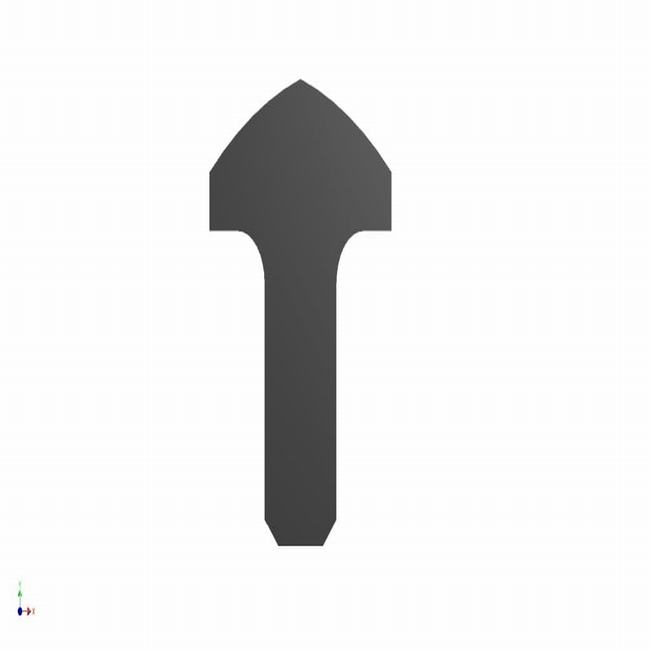

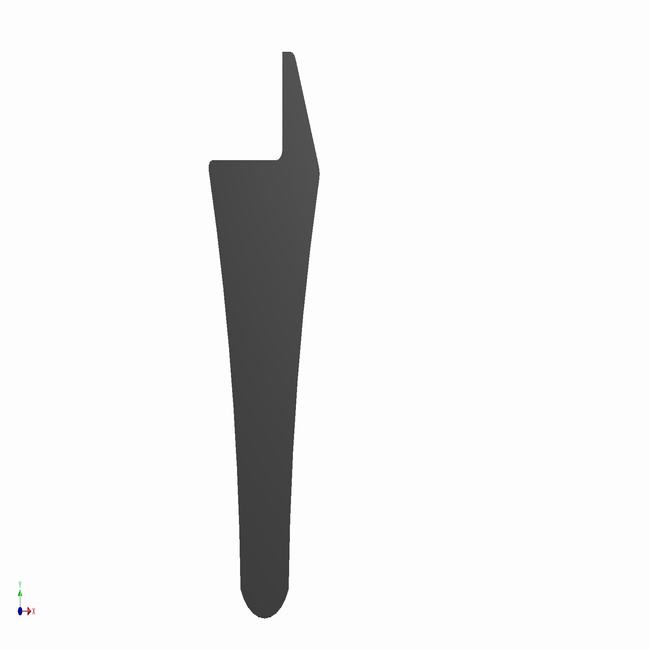

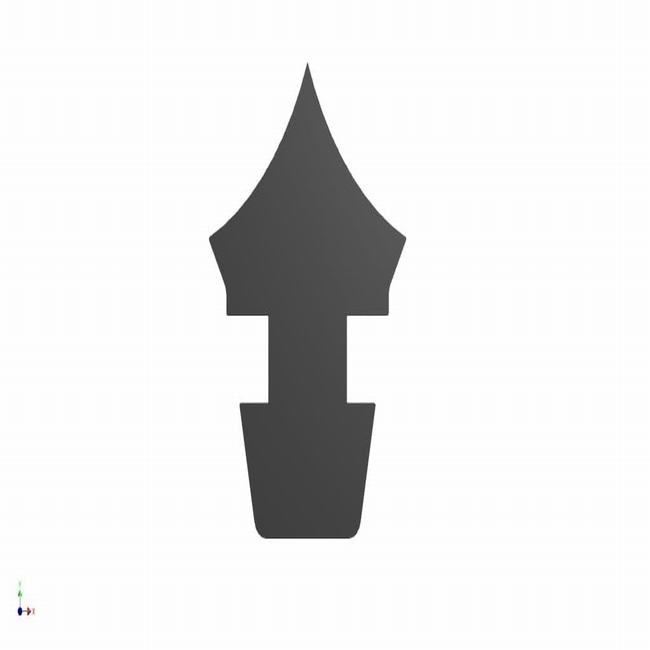

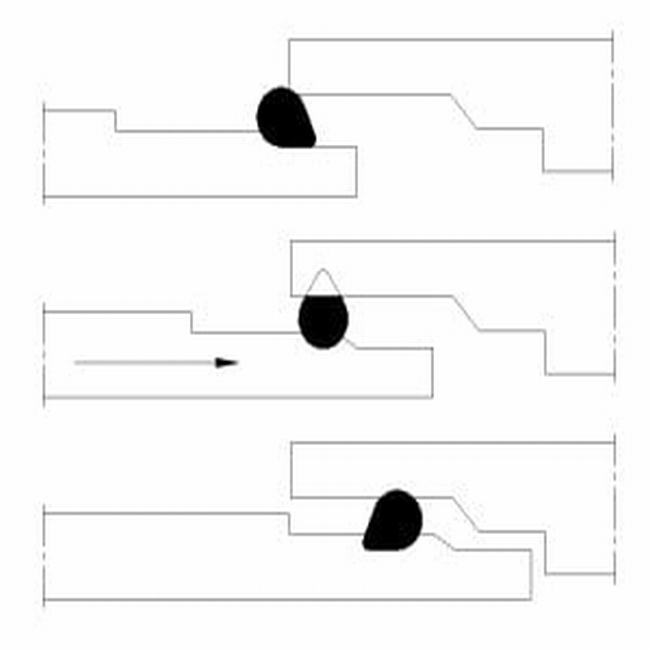

- Rubber Gaskets: Rubber gaskets are the most commonly used sealing solution for concrete pipes. These gaskets are typically made of EPDM (Ethylene Propylene Diene Monomer) rubber or neoprene rubber and are installed in the pipe joints to create a watertight seal. The gaskets are compressed between the spigot (male end) and the bell (female end) of the pipes when they are joined, forming a secure seal against leakage.

- Mastic Sealants: Mastic sealants, such as butyl rubber or bituminous compounds, are often used in combination with rubber gaskets to enhance the sealing effectiveness of concrete pipe joints. These sealants are applied to the joint surfaces before inserting the rubber gaskets, filling any voids or irregularities and providing additional sealing protection against water infiltration.

- Concrete Admixtures: Concrete admixtures, such as integral waterstops or crystalline waterproofing additives, can be incorporated into the concrete mix during pipe manufacturing to improve the impermeability and durability of concrete pipes. These admixtures work by reducing the permeability of concrete and enhancing its resistance to water penetration, helping to minimize the risk of leaks through the pipe walls.

- External Joint Wraps: External joint wraps, also known as wrap-around seals or band seals, are installed around the exterior of concrete pipe joints to provide additional protection against water infiltration. These wraps are typically made of rubber or synthetic materials and are tightly secured around the joint area to create a secondary barrier against leaks.

- Grout Injection: Grout injection is a method used to seal leaks in existing concrete pipes by injecting specialized grout materials into cracks, voids, or damaged areas. The grout material fills the gaps and forms a solid, impermeable seal, restoring the integrity of the pipe and preventing further leakage.

- Flexible Pipe Liners: Flexible pipe liners, such as cured-in-place pipe (CIPP) liners or high-density polyethylene (HDPE) liners, can be installed inside concrete pipes to rehabilitate aging or deteriorated pipelines and provide a new impermeable lining. These liners conform to the shape of the existing pipe, creating a seamless, watertight barrier that prevents leaks and extends the service life of the pipeline.

- Joint Repair Systems: Joint repair systems, including injection grouts, epoxy resins, and specialized repair mortars, are used to repair damaged or deteriorated concrete pipe joints. These systems typically involve filling or coating the joint area with a durable, waterproof material to restore the joint’s integrity and prevent leakage.

When selecting sealing for concrete pipes, it’s essential to consider factors such as the pipe diameter, joint configuration, operating conditions (e.g., pressure, temperature), and the severity of the application environment to ensure proper sealing and long-term performance of the piping system. Additionally, proper installation and maintenance practices are critical for ensuring the effectiveness and durability of concrete pipe seals.